Custom your nickel alloy tubing products with advanced equipment, multi-diameters, different alloy material, wall thickness, and specifications. Low MOQ from 2000 kgs, high quality manufacturing, offer free sample delivery!

Nickel Alloy Tubing Supplier & Manufacturer in China - HZW

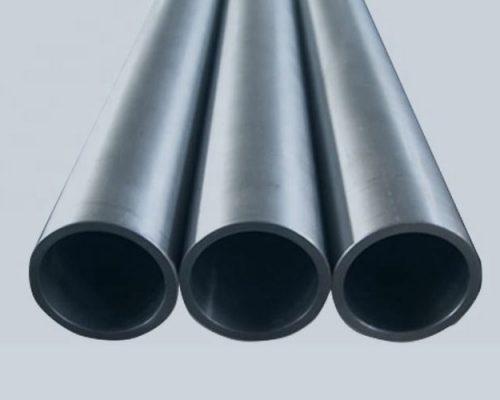

The seamless and welded nickel alloy tubing products are named according to its main standard which is the grade. Implying, they have special features compared to the normal steel tubing.

HZW nickel alloy tubing products come in many different custom-made shapes and specifications that can be specifically designed to fit your tubing project.

For more information about seamless and welded nickel alloy tubing products, contact HZW expert team now!

| Form | Seamless/Welded |

| Application | Chemical plant, petro-chemical plant, pulp & paper mill, food & beverage plant, oil & gas industry, other industries you can check below guides |

| Outer Diameter (mm) | 0.26-1300mm or according to customer’s requirement |

| Wall Thickness (mm) | 0.022-30.0mm or according to customer’s requirement |

| Length | 3 meters and 6 meters or customer’s requirement |

| Standard | ASTM, ASME, EN, JIS, DIN, GB/T, etc |

| Process Method | Cold Drawn or Cold Rolled |

| Price Item | EXW, FCA, FOB, CFR, CIF, DDU or as negotiation |

| Payment | Our company accepts normally Paypal, T/T, and L/C payments. Call or email us if you need to use any new payment procedures |

| Delivery Time | It depends on your pipes order total quantity and stock of these mother origin materials. Usually from the start of the order to the completion of production is about 3-4 weeks |

| Quality Requirement | Mill test certificate will be offered with shipment, the third party inspection is available |

| Main Markets | Europe, North America, Middle East, Southeast Asia |

| Machanical Test | Tension test, flaring test, flattening test, hardness test, hydraulic test, etc. |

| Metal Test | High or low temperature impact test, metallographic analysis |

| Chemical Analysis | As tubing products standard |

Our HZW professional team are experienced at tubing packaging to assure no any damages of products during transportation.

- Standard Export Packaging;

- In bundles with waterproof material, in wooden cases;

- Customized packaging as your request (Logo or other contents accepted to be printed on the pipes packaging);

- Other special packaging will be designed as customer’s request;

- Shipping port: Shanghai, Ningbo or as your request.

When you want to purchase nickel alloy tubing products here, the following information should be clarified before order:

1. Consult: We will recommend the right grades and types of tubing products to you after being informed by your requirements.

2. Quotation: We will supply you with our detail quotation according to our tubing products with the best quality and price.

3. Process Evaluation: Buyers and our engineers team carefully evaluate and discuss all the details of the order to exclude any misunderstanding.

4. Placing The Order: If you have no doubts, we will send you the proforma invoice, and then we will sign a sales contract for your reference.

5. Production: We will arrange the new production as soon as receiving your signed sales contract and deposit payment. The updated news about production will be sent and informed to the buyer during the production period.

6. Inspection: The whole production procedure will be under regular inspection and strict quality control. The complete pipes will be tested to make sure they can work very well before shipment.

7. Delivery: We will arrange the delivery as the related terms in the contract after the confirmation by the buyer.

8. Custom Clearance: We will supply and deliver all the pipes and tubes shipping documents to the buyer and ensure a smooth customs clearance when import.

9. Technical Support and After-sales Service: We will offer 24/7 professional technical support and service for our every buyer. Email us or call us any time, any day. We’ll have your problem fixed in short time.

If you also want to buy nickel alloy tubing products from us or require service support, please don’t hesitate to contact us at any time.

Nickel Alloy Tubing Products Materials & Grades

HZW manufacture high quality nickel alloy tubing products, such as:

Alloy 400, K-500, 718, 625, 601, 600, 825, 800, 800H, 800HT, C22, C276, B, B2, B3, C4, C2000, G-35, 230, X750, 617, 925, GH2132, GH2747, GH3044, GH3030, GH3128, GH4033, GH4145, GH4169, GH4199.

For more information about nickel alloy seamless and welded tubes, contact HZW expert team now!

How Nickel Alloy Tubing Products Made?

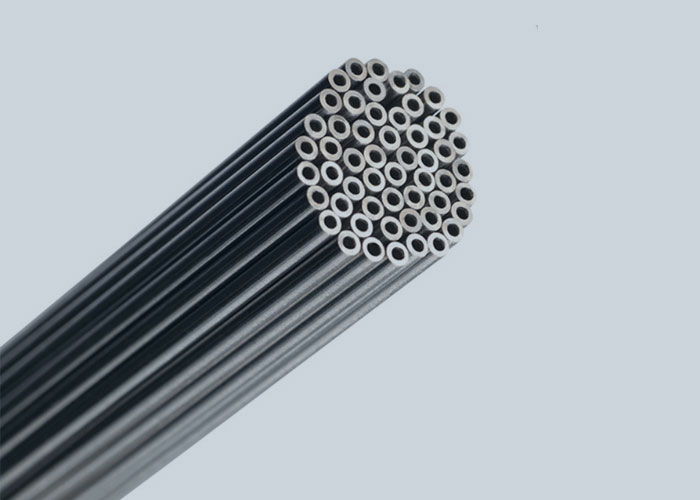

Most people don’t know how the nickel alloy tube is made, instead, they always see a lot of nickel alloy tube in plant or industrial field, but the truth is making nickel alloy tubes is not easy than you imagined.

Basically, there are following steps for nickel alloy seamless tubing products making at HZW:

That’s all the steps in left infographics for how the nickel alloy tubes was made, contact our team now!

Your Reliable Nickel Alloy Tubing Supplier & Manufacturer in China - HZW

Nickel Alloy Tubing Products: The Ultimate Guide

What are the applications that nickel alloy tubing can be used?

Nickel alloy tubings are used in many fields, such as:

- Ocean: marine structures in the marine environment, seawater desalination, seawater aquaculture, seawater heat exchange, etc.

- Environmental protection: flue gas desulfurization device for thermal power generation, wastewater treatment, etc.

- Energy: atomic power generation, comprehensive utilization of coal, ocean tide power generation, etc.

- Petrochemical: oil refining, chemical and chemical equipment, etc.

- Food Industry: salt making, soy sauce brewing, etc.

In many of the above applications, ordinary stainless steel 304 seamless pipe is incompetent. In these special fields, special duplex stainless steel is indispensable and irreplaceable.

In recent years, with the rapid development of the economy and the continuous improvement of the level of the industrial field, more and more projects have chosen nickel alloy seamless tubes for use.

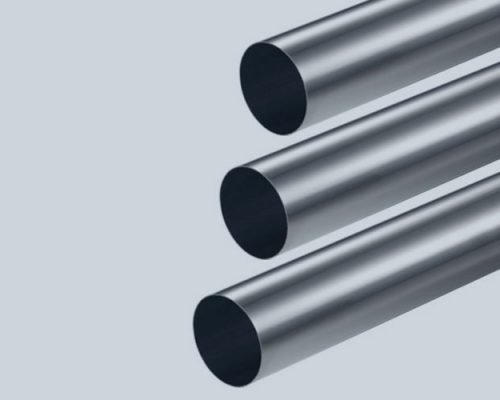

Features of nickel alloy tubing

- Excellent oxidation resistance at high temperatures

- Good carbonation resistance

- Good oxidation resistance in sulfur-containing atmosphere

- Good mechanical properties at room and high temperatures

What are the production standard of nickel alloy tubing?

HZW made nickel alloy tubing is according to standard ASTM, ASME, EN, JIS, DIN, RUSSIA GOST, GB/T, etc. And it can be customized as your requirements.

How to choose your nickel alloy tubing manufacturer in China?

HZW is one of the leading nickel alloy tubing manufacturers in China.

HZW provides superb tubes products and manufacturing services for your every tubing projects.

Our company bears no compromise on seamless tubes quality. We use the best quality mill origin materials along with the advanced equipment and precision production processes.

We revise the orders and take thorough insights before forwarding the order to the final production line. This makes sure the every production is carried out in the most effective manner with zero errors.

If you want to purchase nickel alloy tubing products, why not contact us here for saving your time and money?

Conclusion

Clearly, more than any other grade of steel tubes, nickel alloy tubing are in a world of their own when it comes to good features.

Custom nickel alloy tubing and solutions allow your project to run more smoothly.

With their numerous benefits, nickel alloy tubing products assure you the best for your project or business tubing solutions.