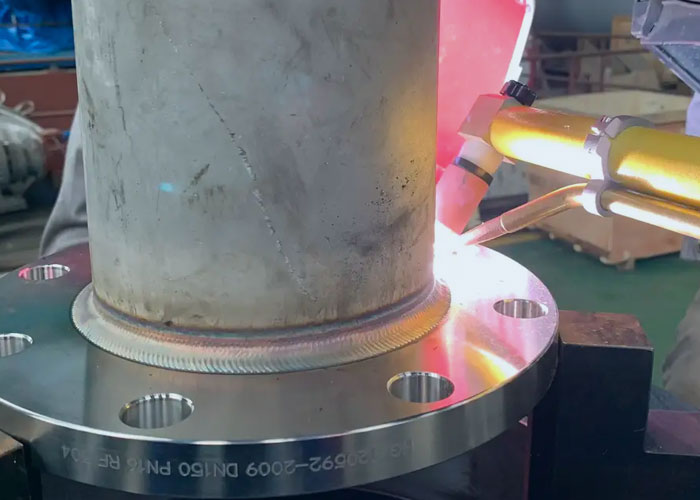

Welding Service

Welding your nickel alloy seamless pipes with advanced equipment, multi-diameters, different alloy material, wall thickness, and specifications. Welding your nickel alloy seamless pipes with advanced equipment, multi-diameters, different alloy material, wall thickness, and specifications.

Impressions From HZW Welding Service

HZW Tubes And Pipes Soultion Provider

Welding Service: Custom Your Pipes And Tubes Project

Welding stainless steel welded pipe refers to a stainless steel welded tube with seams on the surface that is welded by bending and deforming a stainless steel strip or stainless steel plate into a circular, square or other shape.

The blanks used for welded stainless steel pipes are stainless steel sheets or strips.

According to different welding methods, it can be divided into arc welded pipe, high frequency or low frequency resistance welded pipe, gas welded pipe, furnace welded pipe, etc.

We can help weld stainless steel pipes and nickel alloy tubes with flanges, tanks, brackets and more for your piping project.

What Is TIG Welding?

Stainless steel welded pipes require deep penetration, no oxide inclusions, and as small a heat-affected zone as possible. Tungsten inert gas shielded argon arc welding has good adaptability, high welding quality and good penetration performance. Its products are widely used in chemical industry, nuclear industry and food industries.

The low welding speed is the shortcoming of argon arc welding. In order to improve the welding speed, many kinds of foreign countries have researched and developed them.

Among them, the welding of multi-electrode and multi-torch is developed from single-electrode and single-torch and applied in production.

In the 1970s, Germany first adopted multiple torches arranged in a straight line along the direction of the weld to form a long heat flow distribution, which significantly improved the welding speed.

Generally, argon arc welding with three-electrode welding torch is used, the wall thickness of the welded steel pipe is S ≥ 2 mm, the welding speed is 3-4 times higher than that of the single welding torch, and the welding quality is also improved.

The combination of argon arc welding and plasma welding can weld steel pipes with larger wall thicknesses.

In addition, 5-10% hydrogen in argon gas, and then using high frequency pulse welding power source, can also improve the welding speed.

TIG welding is suitable for the welding of austenitic and ferritic stainless steel pipes and tubes.

What Is High Frequency Welding?

High-frequency welding technology has been used in the production of carbon steel welded pipes for more than 40 years, but it is a relatively new technology for welding stainless steel pipes.

The economy of its production makes its products more used in the fields of architectural decoration, household appliances and mechanical structures.

High-frequency welding has higher power supply, and can achieve higher welding speed for steel pipes with different materials and outer diameters and wall thicknesses.

Compared with argon arc welding, its welding speed is more than 10 times.

Therefore, the production of general-purpose stainless steel pipes has high productivity.

Because of the high speed of high-frequency welding, it is difficult to remove the burrs in the welded pipe.

At present, high-frequency welded stainless steel pipes cannot be accepted by the chemical and nuclear industries, which is one of the reasons.

From the perspective of welding materials, high-frequency welding can weld various types of austenitic stainless steel pipes.

At the same time, the development of new steel grades and the progress of forming welding have also successfully welded steel grades such as ferritic stainless steel AISI409.

What Is Combined Welding Technology?

All kinds of welding of stainless steel pipes have their own advantages and disadvantages.

Combining several kinds of welding to form a new welding process to meet people’s requirements for the quality and production efficiency of stainless steel welded pipes is a new trend in the current development of stainless steel welded pipe technology.

After several years of exploration and research, the combined welding process has made progress, and the production of stainless steel welded pipes in Japan and France has mastered a certain combined welding technology.