Surface Treatment Service

For Tubing Products

Surface Treatment

Surface finishing processes are used to improve the tubes and pipes appearance, corrosion resistance, and adherence of a manufactured product. With methods including polishing, brushing, painting, logo printing, we can make your pipes and tubes products have the desired look and feel you want.

HZW provides a wide range of surface finishing services to supplement our production services. Contact our customer service team for a quick quote if you need a perfect finish for your tubing products or other market-ready piping products. Our skilled expert team handles the finishing process with the utmost care and efficiency.

Polished stainless steel pipes and nickel alloy tubes are the models with polishing bright surface finish produced by different polishing equipment and method.

As we know, pipes and tubes will form a black or gray oxide scale on its surface finishes after thermal processing, mechanical processing or placing it for a certain period of time.

Its main components are Cr2O3, NiO and very insoluble FeO and Cr2O3,

These components affects the appearance quality. What’s more, they also affect the performance of the piping product.

As a mature surface treatment method, finish polishing has been widely used.

Polishing can further improve the corrosion resistance and bright effect of tubes.

The color painting is the traditional process of applying a wet liquid paint to the stainless steel pipes and nickel alloy tubes for finishing.

The pipes and tubes production processes will use a spray, pump, or pressurized vessel to deliver the wet paint evenly.

This color painting pipes and tubes are supplied as end user’s demands.

It is a surface process method that forms lines on the surface of the pipes and tubes by grinding products to achieve a decorative effect.

According to the different lines after drawing, it can be divided into: straight drawing, chaotic drawing, corrugation, and swirling.

Used on metals where a series of tiny parallel lines are scratched onto the surface with a wire brush or polishing tool.

In industrial production process, there are many new products appearing and producing, but traditional industries and materials still have their unique charm and function, and they often occupy an important position in use, and the frequency and probability of use are also very high.

Traditional materials like steel are very common in our industrial life.

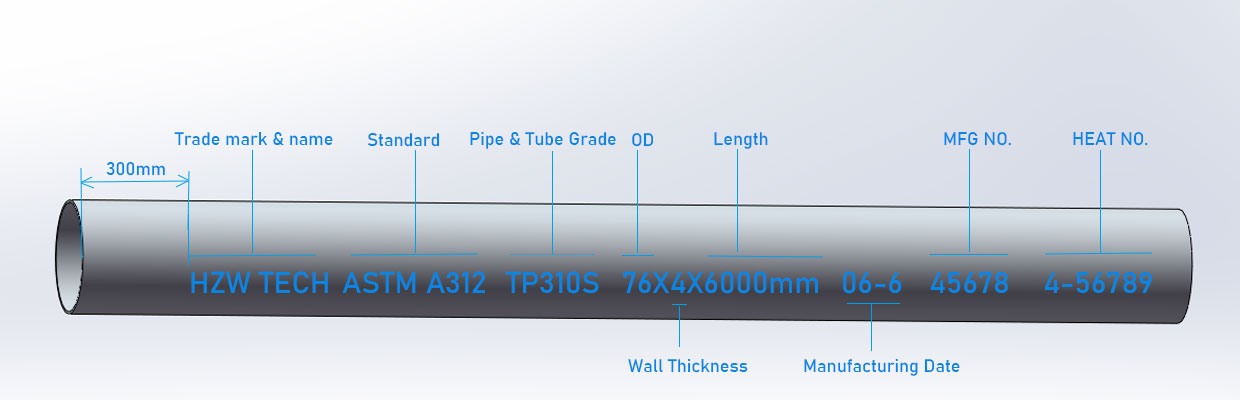

For the production and marking of stainless steel tubes, the inkjet printer industry has more experience, so that the stainless steel piping industry can improve the marking speed in production.

To meet the needs of customers’ industrial coding, HZW Technology is committed to meet the special requirements of customers logo printing, providing a full range of solutions for marking stainless steel pipes and nickel alloy tubes. Its solutions are economical, cost-effective, simple to maintain, perform well and operate reliably.